Ceria slurry

Complete turnkey solution to meet the polishing requirements of ILD. The ceria powder that conforms to the semiconductor CMP process is between 30-300 nanometers.

In addition to providing effective grinding particles in the formula, we also added our self-developed dispersing materials on top of a good acid-base dispersion system. Suitable for various thin films that remove silicon dioxide.

Different models will be reflected in different removal rates. When selective materials are added, they will exhibit selectivity for removal or protection.

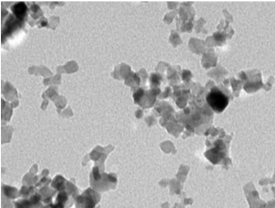

Fumed Ceria

Particle size:80nm~300nm

Application:ILD CMP

According to CMP process requirements, the size and morphology of abrasive particles can be adjusted

Using small-sized particles can provide excellent defect and scratch performance

Milky White

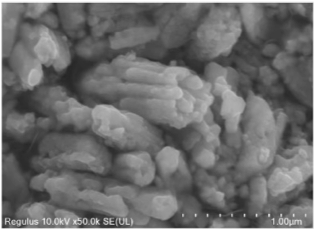

MOFs Ceria

Particle size:5nm~180nm

Application:STI CMP

This CMP process requires adjustable abrasive particle size and morphology

The uniform morphology and low particle size distribution deviation provide excellent defect and scratch performance

Adding different additives can achieve stop on nitride/poly

Milky White

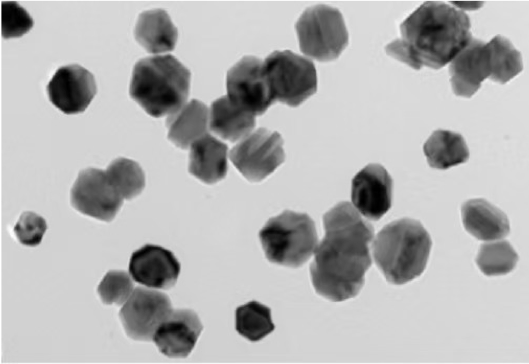

Coprecipitation Ceria+PR

Particle size:180nm~400nm

Application:photo mask/wafer glass

Cerium oxide grinding particles add PR elements in the production process

Has stronger mechanical grinding characteristics and higher planarization removal rate

Brownish Red